PRODUCTS

Shuttle shelves

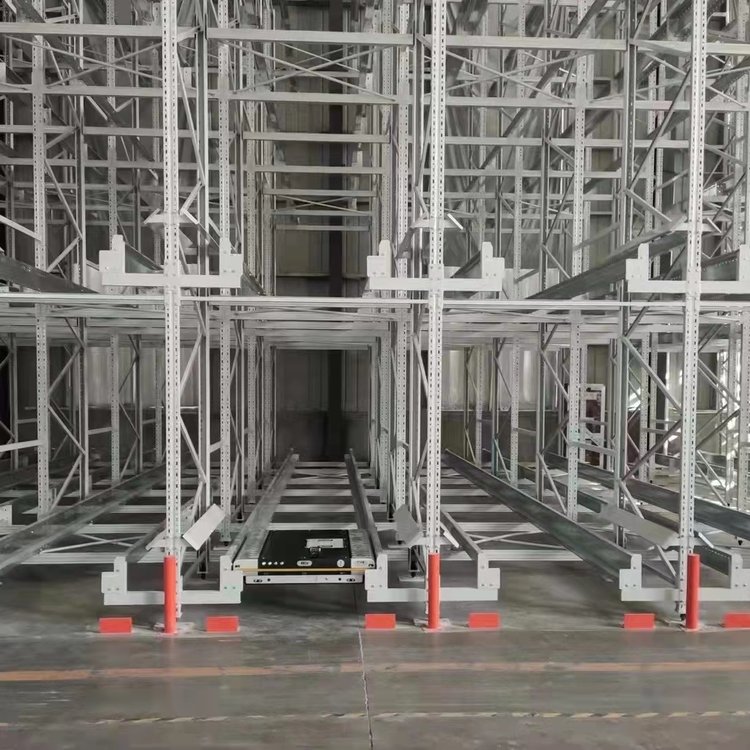

Product Struction

The shuttle shelf system is mainly a high-density storage system composed of shelves, shuttle trucks, forklifts, and software systems. Its working principle is a shuttle car operated by radio remote control, which can carry pallet goods and run on the guide rail; Use a forklift to lift the pallet of goods from the upper shelf or from the lower shelf; Mobile shuttle trucks can be placed in different alleys using forklifts, and multiple alleys can share a shuttle truck.

2. Features of shuttle shelves

1) Fully utilize warehouse space, high-density storage, and can utilize approximately 80% -85% of the space;

2) High operational efficiency, the shuttle car can adopt automatic or manual modes, continuous entry and exit modes, and workers can also operate multiple shuttle cars at the same time, greatly reducing the waiting time for work and greatly improving work efficiency;

3) The structure is very stable and has a high safety factor. Due to the shuttle car running in the tunnel, forklifts do not need to enter the interior of the shelves, avoiding collisions between forklifts and shelves, thus ensuring the safety of personnel and equipment;

4) The storage and retrieval method of goods can achieve first in, first out or first in, last out;

5) The shuttle car can achieve automatic sorting, inventory and other functions;

3. Product specifications

The size specifications of the shelves are customized based on the size of the pallets. The conventional pallet size is 1200 * 10001200 * 1200, and the height of the shelves is determined by the height of the goods, the height of the warehouse, and the lifting height of the forklift. The number of shuttle cars is determined by comprehensive factors such as tunnel depth, total cargo volume, shipment batch size, and shipment frequency.

4. Suitable warehouse parameters

5. Applicable industry/type of goods

1) Foods, beverages, chemicals, tobacco, and other single variety goods with large quantities and single variety,

2) Cold storage operation: reduce low-temperature operation time, improve work efficiency and safety

3) Term management: warehouses with strict requirements for item batches and requiring first in, first out operation management

·4) Increase storage capacity: warehouses with limited storage space that require maximum utilization of space

6. Product advantages

1) Customization of products based on customer actual needs, independent research and development;

2) High safety and stability;

3) The product can be managed in layers and accessed flexibly;

4) Customize the system according to customer needs and can also interface with ERP systems.

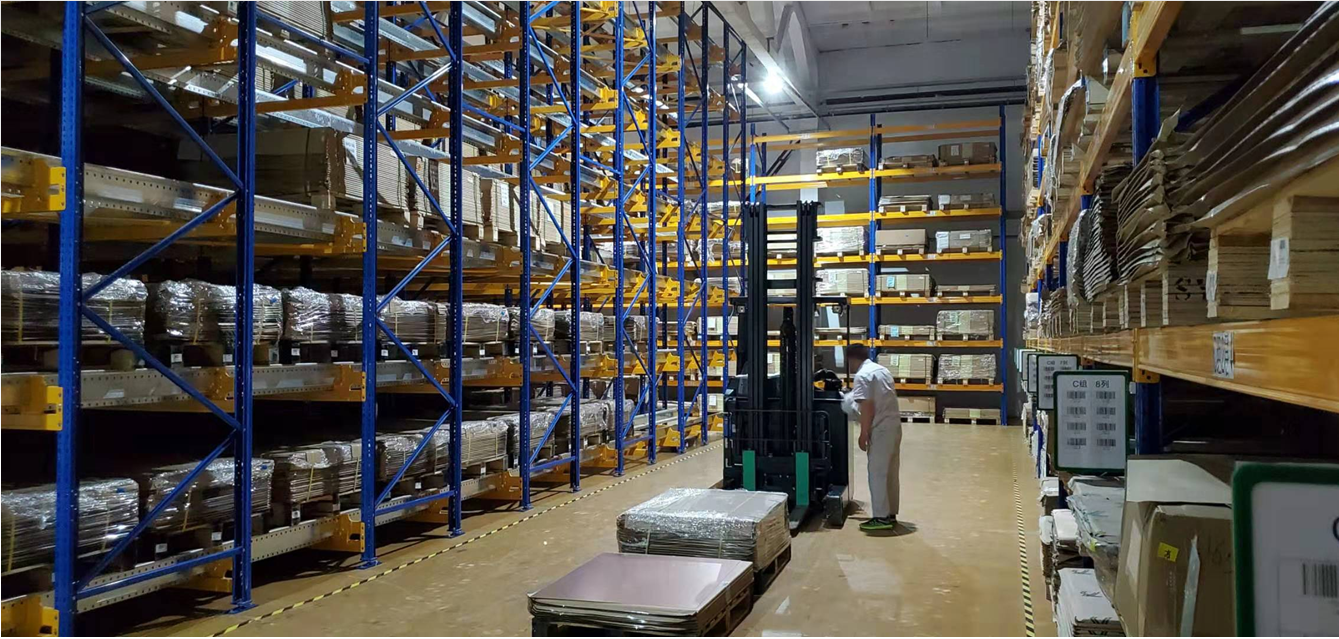

7. Product image